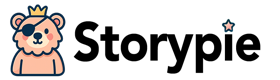

A Story of a 3D Printer

Hello, world! You might not recognize me at first, but I bet you’ve seen the amazing things I can do. My name is the 3D Printer, and I have a kind of magic. I don’t pull rabbits out of a hat or make coins appear from behind your ear. My trick is even better. I can build real, solid objects out of nothing but an idea and some special material. You can think of me as a robot artist. Instead of using a paintbrush on a canvas, I use a tiny nozzle or a special light. Instead of painting on paper, I build things up in the air, drawing one super-thin layer at a time. I might use melted plastic that looks like colorful spaghetti, or a special liquid that hardens under a beam of light. I stack these layers, one on top of the other, over and over again, until a whole new object grows right before your eyes. Before I was invented, if someone wanted to create a new part for a machine or a model of a new toy, it took a very, very long time. They had to carve it or mold it by hand. I was born from a powerful idea to make things much, much faster.

My story really begins in the early 1980s with a clever and curious inventor named Chuck Hull. He worked at a company that used ultraviolet, or UV, light to put thin, tough coatings on things like tables. He was a problem-solver, but he had a big problem of his own. Whenever his team needed a small plastic part to test a new idea, they had to wait for weeks to get it made. This was slow and frustrating. One day, a thought sparked in his mind. He worked with liquid plastic, called photopolymer, that turned solid when UV light hit it. He wondered, what if I could use a beam of UV light like a super-fine pen to draw a shape on the surface of this liquid? The light would harden just that one sliver-thin layer. Then, he could lower it just a tiny bit, add a new layer of liquid on top, and draw the next part of the shape. Could he build an entire object, layer by layer, right out of a vat of goo? The idea was so exciting he could barely wait to try it. He worked tirelessly in his lab after everyone else had gone home, tinkering with chemicals and machines. Finally, the big night arrived. On March 9th, 1983, he was ready for the first real test. The lab was hushed as my first motors whirred to life. A bright beam of UV light danced across the dark surface of the liquid. Slowly, almost magically, a solid shape began to emerge. The first thing I ever created wasn’t a toy or a spaceship. It was a simple, small, black plastic eyewash cup. It wasn't beautiful, but it was perfect because it proved that Chuck's incredible idea worked! He knew he had something special. On August 8th, 1986, he received an official certificate called a patent for his process, which he named 'stereolithography.' This meant the idea was all his. He then started a company to help me grow and meet the world.

For a long time, I was a very large and expensive machine. I lived only in big factories and fancy design labs, helping engineers build parts for cars and airplanes. But just like people, inventions grow up and change. I’ve gotten smaller, smarter, and much more common. Today, I don’t just live in factories. I live in your school’s science lab, in workshops, in hospitals, and even on desks in people’s homes! I’m busier than ever, and the jobs I do are amazing. I help doctors plan difficult surgeries by printing exact models of a person’s bones. I build lightweight parts that make airplanes and race cars faster and more efficient. I can even print a custom toy designed by a kid, bringing their unique drawing to life. I’ve even traveled to space, where astronauts can use me to print a replacement tool if one breaks on the International Space Station. Looking back, I see that I was more than just a machine to make plastic parts. I am a machine that turns imagination into reality. I help people hold their ideas in their hands. So next time you have a brilliant idea, remember me. If you can dream it, one day you just might be able to print it.

Activities

Take a Quiz

Test what you learned with a fun quiz!

Get creative with colors!

Print a coloring book page of this topic.