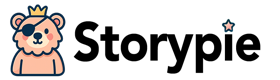

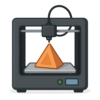

The 3D Printer: Building Dreams from Light and Dust

Before I could tell you my story, you have to imagine a world where every new idea had to be painstakingly carved out of a solid block. Think of a sculptor with a huge piece of marble, chipping away for weeks just to see if the shape in their head would work in the real world. That was how things were made. It was slow, it was expensive, and so much material was wasted, ending up as dust on the floor. That was the world before I was born. I am a 3D Printer, and I changed the very way we create. My story begins not in a grand workshop, but in the mind of an engineer named Chuck Hull. In the early 1980s, Chuck worked for a company that made furniture, and he was frustrated. He designed new, small plastic parts for prototypes, but he had to wait for weeks, sometimes months, for a factory to create just one sample for him to test. He knew there had to be a better, faster way to turn a design on a computer screen into a solid object he could hold in his hand. He didn't want to subtract from a block; he wanted to add, to build, to grow an idea from nothing.

Chuck’s big idea didn't come from a lightning strike, but from the steady glow of his work. He was working with ultraviolet lamps to cure, or harden, thin layers of acrylic coatings on tabletops. He watched the liquid plastic instantly turn solid under the light and wondered, what if he could do that over and over again, in specific patterns, one layer on top of the other? That thought was the spark that brought me to life. He called his method stereolithography. It sounds complicated, but you can imagine it like this: picture a small tank filled with a special liquid goo, a photopolymer that hardens when hit with UV light. A computer guides a tiny, precise beam of that light, making it dance across the surface of the liquid, drawing the first thin slice of an object and turning it solid. Then, a platform lowers the brand-new layer just a fraction of a millimeter deeper into the goo, and the light dances again, drawing and hardening the next layer right on top of the first. This continues, layer after delicate layer, until a complete, three-dimensional object rises from the liquid. The first time this ever happened was on the quiet night of March 9th, 1983. In Chuck's lab, with only the gentle hum of my machinery for company, I created my very first object. It was a small, black teacup. It wasn't big or fancy, but it was perfect. It was proof that an idea could be built from light and liquid, one layer at a time. That night, I wasn’t just a machine; I was a promise of a new kind of creation.

After my birth, I spent my early years in high-tech labs and big engineering firms. I was large, expensive, and a bit of a specialist. But inventors are restless people, and soon others began to imagine new ways for me to work. A man named S. Scott Crump had his own clever idea in the late 1980s. He wanted to make a toy frog for his daughter and thought of using a hot glue gun to build it layer by layer. This led him to develop a new process called Fused Deposition Modeling, or FDM. You can think of it as a robotic, super-precise hot glue gun that melts a thin thread of plastic, called a filament, and draws with it, building an object from the ground up. This invention was a game-changer for me. It meant I could be built smaller and much more cheaply. Suddenly, I wasn't just for giant corporations anymore. I started finding new homes and new families. I moved into classrooms, where students could design and print their own inventions. I found my way into doctors' offices, where I print precise models of patients' hearts and bones so surgeons can practice complex operations before ever making a cut. I even went to work with aerospace engineers, helping them create lightweight, intricate parts for rockets destined for space. From a simple teacup, I had grown up to build the tools that were shaping the future, and I was now in the hands of creators everywhere.

My true purpose was never just about making teacups or even rocket parts. It has always been about making ideas tangible. I am the bridge between the imagination and the real world. For centuries, a brilliant idea could remain trapped in someone’s mind, too difficult or expensive to create. I changed that. I gave inventors, artists, scientists, and students the power to fail quickly, learn instantly, and innovate faster than ever before. If a design doesn't work, they don't have to wait weeks for a new prototype; they can tweak the file and print a new version in a matter of hours. This freedom to experiment and create has accelerated progress in countless fields. And my story is still just beginning. People are now using me to explore printing custom medicines, building affordable houses in remote areas, and even preparing to print tools and habitats on other planets. My journey started with a simple problem and a glowing light, but it has shown that the most powerful thing we can build is a new idea. With a bit of creativity, anyone can use me to construct a better world, one amazing layer at a time.

Activities

Take a Quiz

Test what you learned with a fun quiz!

Get creative with colors!

Print a coloring book page of this topic.